Home Improvement:

Vacuum Press

The enabling technology of gluing wood veneer tightly to cabinet doors is a vacuum bag. This is a vacuum pump connected to a plastic bag that holds the door with the freshly glued (still wet) veneer in place. The result is like a ton of weight evenly distributed on the veneer, bonding it permanently to the substrate door.Checklists

The same Excel Spreadsheet with rows for each cabinet also has columns calculating the measurements for each door and drawer front. For each sized part, there is a definite series of steps with various cuts and trimming that have to be done in order. The only way to get this right in this size of a project is to generate a custom checklist with detailed measurements for every single piece.Veneered Doors

For that minimalist

contemporary look

I used several veneering books including:

“Veneering: A Foundation Course” by Mike Burton

and

“Woodworker's Guide to Veneering & Inlay:

Techniques, Projects & Expert Advice for Fine

Furniture” by Jonathan Benson.

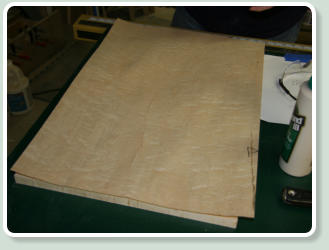

Here is a strip of maple about to be glued on the

MDF substrate. The substrate is trimmed on the

one edge only. Other edges will be trimmed just

before their strips are to be glued.

The strip is glued and clamped to the substrate

Sides are trimmed along with the now-cured bottom

maple strip

The side strips are then glued and clamped. Note

the bookkeeping on the checklist. This is very

important to avoid mistakes especially when dealing

with fractions of an inch.

...and trimmed using the router surface jig.

After the top edge is glued on, final trimming is done

on the drum sander, which leaves the assembly

perfectly flat and ready for veneer.

Glue is rolled on. This has to be done quickly as

this particular glue starts drying rapidly. Also the

veneer curls and expands (at least 1/4”)

immediately when contacting the wet glue. Later

on, we discovered that using Urea Formaldehyde

glue such as Uninbond800 made the assembly WAY

easier. No expansion and plenty of open time until

you apply heat to cure it.

It’s important that both the substrate and veneer are

marked lightly in pencil for which way is up and

which side is the face versus the rear of the panel.

The whole point of buying the veneer lie we did is to

get each panel to have grain flowing into the panels

adjacent to it.

Into the bag it goes. The vacuum pump is strong

enough to get small wrinkles out quickly with a little

help from a wooden roller.

That was the back of this particular panel. For the

front, we wanted a gentle curve on the side edges. it

is something of a pillowing effect, but only at the

sides. This is done on the shaper with a vertical

cutting router bit

The finished profile. The veneer will have no

problem curving around this edge. Note the writing

on the panel to show which way is up and also that

this is the face (not the rear) of the panel. This will

not show through the veneer and I can’t stress

enough the importance of marking everything.

Exotic Birdseye Maple

These doors can only be ruined with handles or knobs. If you look at the expanded picture (click above), you’ll see that the grain of these panels is a breathtaking figured birdseye. The grain is consistent because every panel came from the same exact tree. A 10 foot trunk is mounted on a giant lathe and “peeled” to make sequential sheets of veneer only 1/40” thick...

...And I bought 17 of those sequential sheets! Most

of the sheets are 110” long by about 37” inches

wide. This means that every cabinet door that I

made had no seam on the front or back. It also

means that base cabinet double doors and the two

drawer fronts above them will have the wood grain

running continuously. You don’t get that at Home

Depot.

Where do you get that?

Solid Maple Edging

This is similar to the cabinets themselves. Each part is mostly made of smooth-as-silk medium density fiberboard, or MDF. It takes glue really well and is considered an optimum substrate for veneer regardless of cost. As in cabinet part construction, this means that the edges need to be faced with solid maple on all sides.

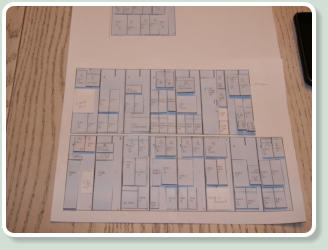

Back to the cabinets. Figuring out where each

piece of veneer should be cut took some planning.

Above is the scale model of the veneer strips (with

defects marked so that I can avoid them). No

mistakes allowed!

Niagara Falls! Well close. This is the Canadian

side, but about 40 minutes away on the Buffalo side

is “Certainly Wood”. They are worth the trip to East

Aurora, NY. While there, eat at the birthplace of the

Buffalo Wing - The Anchor Bar.